-

What is the use of the Christmas tree valve on an oil well?

The various valves on the “Christmas tree” collectively form the safety control center of the oil well. They work in coordination according to functions such as main control, daily production and emergency maintenance. Main Control Valves (Safety Core) Upper Main Valve: Usually ...Read more -

What is the historical development process of pipe forging technology?

The history of pipe fitting forging technology is very long, and its core idea can be traced back to the Neolithic Age when humans began to use metals. Phase One: Ancient Hand Forging From the end of the Neolithic Age to around 2000 BC, China had already applied cold forging techniques to make ...Read more -

Why are there differences between British standard and American standard threads, and why are these differences not significant?

They have many differences: 1. First, look at the thread angle The most accurate method is to measure with a thread gauge. 60° is for the American standard, and 55° is for the British standard. If no tools are available, for pipe threads, you can observe the sealing method: American standard NP...Read more -

Why is the pipeline industry still indispensable?

The metal pipe industry has not been phased out. On the contrary, it has found an unshakable space for survival and development in the new era due to its continuous innovation in key areas and its irreplaceable unique performance. Mainly because metal pipes undergo self-renewal Technical core: Th...Read more -

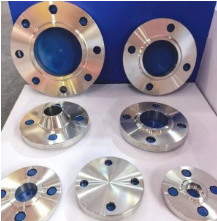

Perfect flange manufacturing process

Our carbon steel flanges adopt a more stable production process, starting from the selection of high-quality raw materials. Each batch of steel is rigorously tested to ensure compliance with standards,laying a stable foundation for production. Our core technology lies in mature forging and machin...Read more -

What is ASME B16.5 and why should we follow this standard?

\”AMSE B16.5\” actually refers to the industrial pipe flange standard formulated and maintained by the American Society of Mechanical Engineers (ASME), and it is the core representative standard of the \”American Pipe Flange System\”. Generally, ASME B16.5 is applicable t...Read more -

Why choose the observation valve? What kinds of valves are there?

Observation valves have gradually become crucial pipe fittings and valves in the current pipeline layout. They provide safety guarantees for the entire pipeline and indirectly reduce safety risks and costs for the entire pipeline system. Observing valves are used to monitor production conditions ...Read more -

The application and features of flange valves in our daily life

Flanged valves are very common and highly effective in industrial pipelines. From factory production lines to urban underground networks, they silently safeguard the transportation processes of various fluids such as water, oil, and gas, ensuring everything runs smoothly. This type of valve is s...Read more -

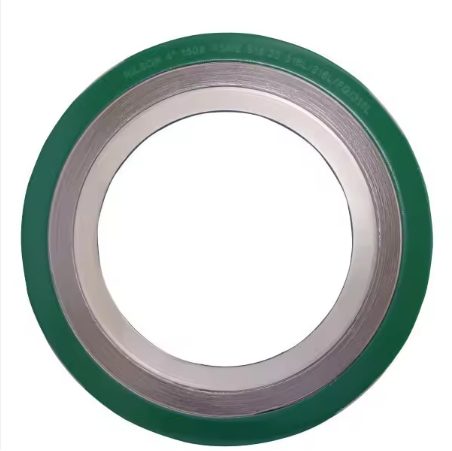

The uses and types of flange gaskets

Main types of flange gaskets Non-metallic gaskets Typical materials: rubber, polytetrafluoroethylene (PTFE), non-asbestos fiber (rubber asbestos). Main uses and features: Widely used in water, air, steam, acid and alkali media, rubber asbestos gaskets were once a common choice. For corrosion-res...Read more -

What are the requirements for the manufacturing process of flange pipe fittings?

Los requisitos centrales del proceso de fabricación de accesorios de tubería bridas, se basan en diferentes procesos (por ejemplo, forja, fundición, mecanizado CNC) y escenarios de aplicación (por ejemplo, alta presión, ambiente corrosivo) Para cumplir con los cuatro objetivos principales de resi...Read more -

Why did we choose Flange? The uses and advantages of Flange

Stainless steel flanges are key connecting components in stainless steel piping systems and can be used for pipe connections. Pipe connection, equipment interface, pump and valve connection, container interface. Flanges have strong adaptability to media and are suitable for corrosive media (acid...Read more -

What grade is the hardest bolt in the world?

Before understanding the bolt grades, we need to first know what hardness ordinary bolts have. The 4.8-grade bolts are almost used in both household and daily life. For the assembly of ordinary furniture, lightweight shelves, motor housing fixation, ordinary boxes, and some non-structural civili...Read more